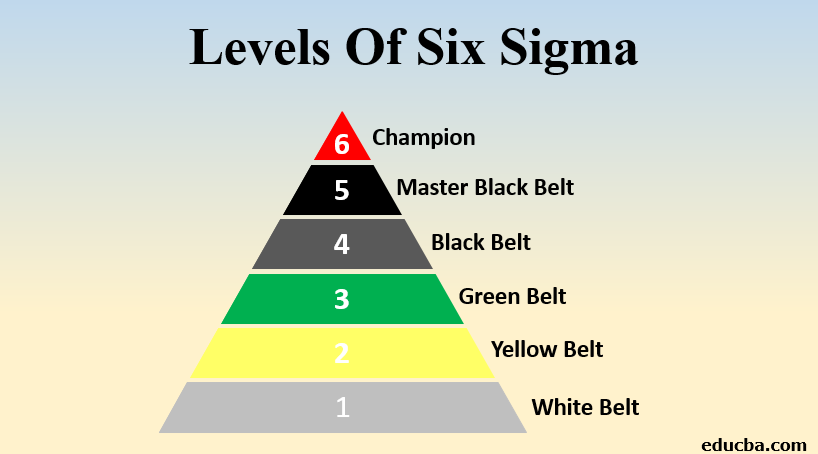

Six Sigma is a data-driven approach to quality aimed at reducing variation and the associated defects wastes and risks in any process. This means a six sigma process produces 34 defects per million opportunities or less as a result.

6 Best Photos Of Six Sigma Dmaic Template Lean Six Sigma Flow Chart Six Sigma Dmaic Process And Six Sigma Defin Templates Process Improvement Lean Six Sigma

6 Best Photos Of Six Sigma Dmaic Template Lean Six Sigma Flow Chart Six Sigma Dmaic Process And Six Sigma Defin Templates Process Improvement Lean Six Sigma

It is a developmental approach to delivering highly efficient and improved processes.

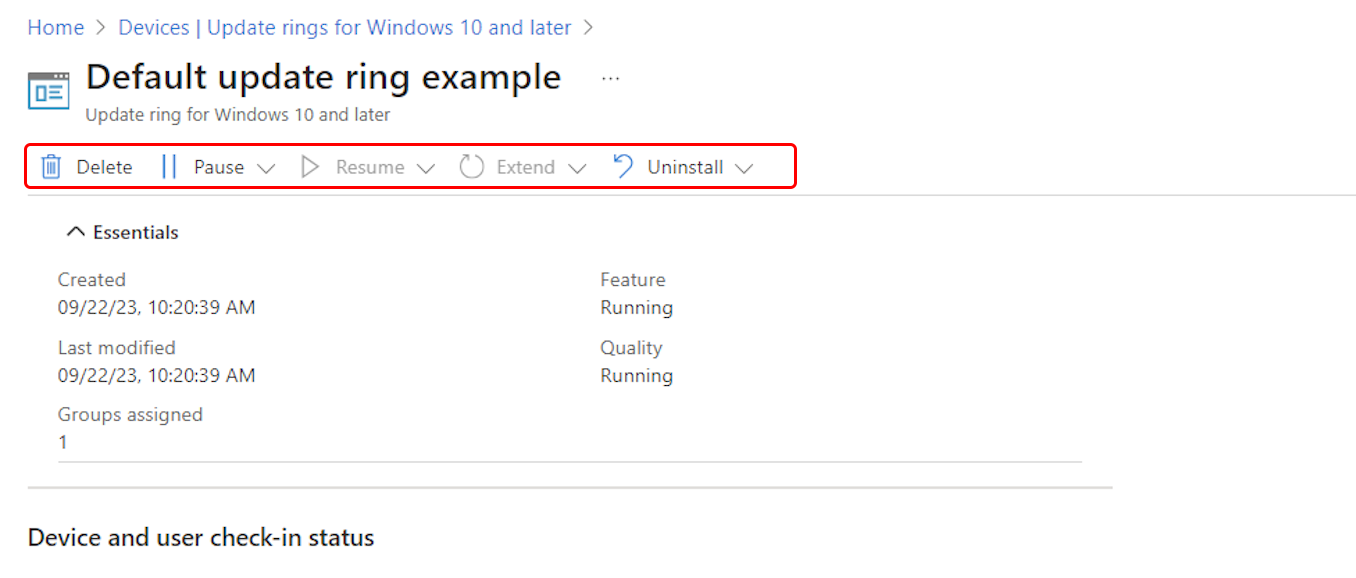

6 sigma process. He will use _____ to show which department is responsible for which steps in the process. The Six Sigma school of thought is all about finding the right focus and tightening up processes around that goal. One of the core techniques behind any process improvement particularly in Six Sigma is DMAIC.

Six Sigma aims at identifying and eliminating errors that cause defects in a process product or service. Six Sigma Green Belt Certification Process Mapping Questions. This article explores the basics of Six Sigma process quality definition and measurement.

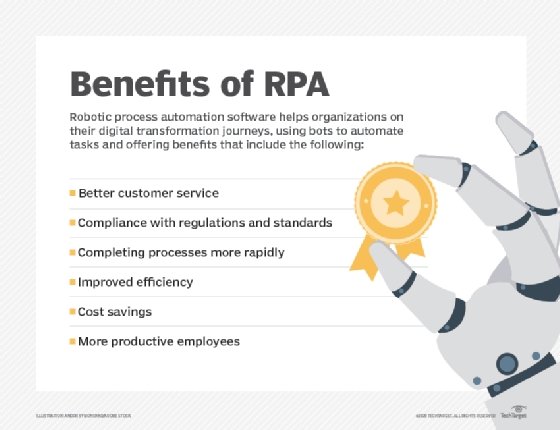

Were going to cover each step in the process and detail how to effectively enact every section. Today six sigma has evolved from the manufacturing industry to other industries. This saves resources time effort and most of all money.

Almost every industry employs six sigma concepts to improve their operations. A process owner is responsible for defining the process vision mission objectives goals KPIs Key Performance Indicators and essential measures associated with the organizational strategies. The Six Sigma DMADV process define measure analyze design verify is an improvement system used to develop new processes or products at Six Sigma quality levels.

μ x1 x2 x3. Define Measure Analyze Improve Control. The word Sigma itself means to measure how much deviation a process has been showing from perfection.

The aim of Six Sigma is to make a process effective with - 9999996 defect-free. Six Sigma is a structured problem-solving methodology. This handy approach pronounced duh-may-ik is the key to employing Six Sigma and beginning your journey to being a process hero.

In a set of data mean μ and standard deviation σ are defined as. This process is also known as DMAIC duh-may-ik its acronym. This concept is employed by management for quality improvements.

Lean Six Sigma is simply a process for solving a problem. Demikianlah pembahasan dari artikel kali ini semoga bermanfaat dan menambah wawasan baru untuk kita semua. The Actual Process Variation is resulted because of Controllable Factors andor Uncontrollable Factors.

DMAIC is a five-step method for improving existing process problems with unknown causes. When a Belt is developing a Macro Process Map to define a complex process he will frequently include activities across various department to capture all the appropriate activity. Six Sigma Components of Variation The variation in process can result due to the Actual Process Variation and the Variation from Measurement System.

Six Sigma is a highly efficient method or process through which organizations can improve their products and services to the nearest perfection. Six Sigma is a data-driven methodology that provides tools and techniques to define and evaluate each step of a process. It can also be employed if a current process requires more than just incremental improvement.

In Six Sigma we want to describe processes quality in terms of sigma because this gives us an easy way to talk about how capable different processes are using a common mathematical framework. The Goal of Six Sigma. It consists of five phases.

The end result should be the reduction of defects from a process. In other words it allows us to compare apple processes to orange processes. Xn n.

It provides methods to improve efficiencies in a business structure improve the quality of the process and increase the bottom-line profit. Roles and Responsibilities of a Process Owner in Six Sigma A process owner in Six Sigma is responsible for managing the process change and process performance. Tujuan penerapan Six Sigma adalah untuk mengurangi fluktuasi terhadap pengeluaran suatu perusahaan sehingga enam standar deviasi Sigma antara rata-rata mean dengan batas perincian terdekat tidak melebihi batas yang di tentukan.

/best-trade-school-graduate-jobs-4125189-v4-31ffe321f61a4cc9bf3ba792c4d46fc9.png)